MOST DRY CLEANERS HAVE HEARD THE DREADED PHRASE FROM THEIR COLLEAGUES, “THEY DID A PHASE I.” FROM THIS POINT ON, DRY CLEANERS ARE LEFT WAITING ON PINS AND NEEDLES TO HEAR WHEN THE RESULTS WILL BE READY. IN THIS ARTICLE, I’LL EXPLAIN WHAT YOU CAN EXPECT DURING A PHASE I AND A PHASE II ENVIRONMENTAL SITE ASSESSMENT.

BY: STEVE HENSHAW

WHAT IS A PHASE I ENVIRONMENTAL SITE ASSESSMENT?

A Phase I Environmental Site Assessment (ESA) or Phase I ESA, is short for a study conducted on a property to evaluate the likelihood of environmental contamination. There is a standard that must be followed under the American Standard for Testing and Materials (ASTM) to satisfy an All-Appropriate Inquiry (AAI), which is the process of evaluating a property’s environmental condition and assessing potential liabilities for any contamination. This is also under Comprehensive Environmental Response, Compensation and Liability Act (CERCLA).

The thing about conducting a Phase I ESA on real estate that has a dry cleaner is that invariably, because of the history of dry cleaning operations, a Phase II ESA is nearly always required as follow-up. In other words, one can be certain that if a property has an active or historical dry cleaner on the site is being considered for refinancing or purchasing, follow-up soil, soil gas or groundwater samples will likely be required.

Download a questionnaire to begin collecting helpful information about your dry cleaning property.

WHAT IS A PHASE II ENVIRONMENTAL SITE ASSESSMENT?

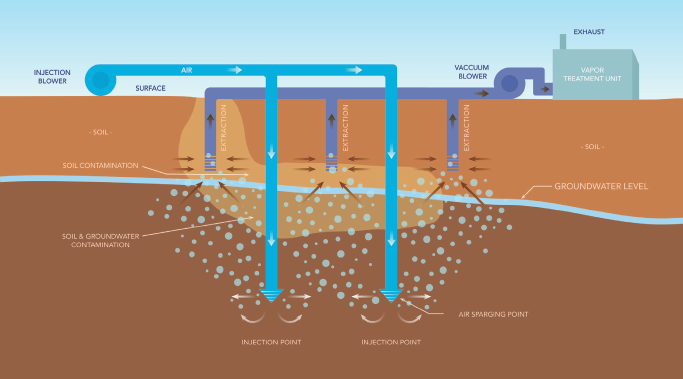

This is a follow-up sampling called a Phase II ESA. While this common terminology is not accurate, it does convey a step further in the process of determining whether a dry cleaner has affected a piece of property. The Phase II ESA, also referred to as a “subsurface investigation” or more commonly “site investigation,” typically consists of collecting a series of soil, soil gas, which includes sampling for vapor intrusion, and groundwater samples and sending the samples to a laboratory to determine if dry cleaning operations have impacted the property negatively through environmental contamination.

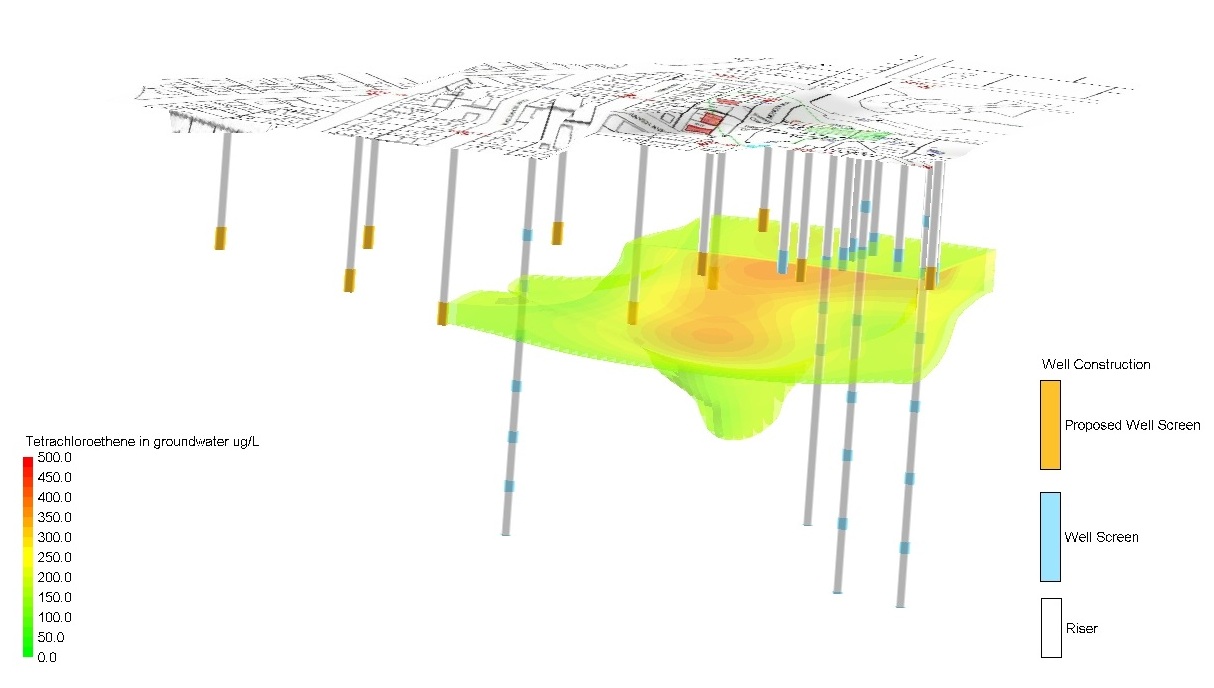

Phase II ESAs initial soil and groundwater samples are collected at a few locations where the highest likelihood of releases has likely occurred. These samples can be collected by hand using hand-held equipment, or by small to large drilling rigs. The type of equipment used depends on the types of soil and depth of groundwater at the site, and whether the samples are collected from underneath the building or outside. These areas are typically current and former dry cleaning machine locations and/or dry cleaner solvent transfer locations. Once collected, the samples are then sent to a laboratory to determine how much, if any, dry cleaner solvents are present in the soil and groundwater. If impacts are present, additional soil and groundwater samples are collected at more locations until the entire area of soil and groundwater contamination has been determined. This process may take several months. Once the extent of soil and groundwater contamination has been determined with Phase II ESA activities, remediation activities can begin.

HOW MUCH DO PHASE I ESAS AND PHASE II ESAS COST?

While a Phase I ESA costs are generally low and predictable, Phase II ESA costs vary by many factors. Some of these factors are “site specific.” For example, the types of soil and depth to groundwater at the site, the length of dry cleaner operations, and even prior operations will influence the cost of a Phase II ESA. Other factors include the reason for conducting a Phase II ESA. For example, if the dry cleaner is thinking about refinancing, the Phase II ESA may consist of the fairly simple question, “Is my site affecting the environment?” If the desire is to know the costs to reach site closure, the cost of a Phase II will be higher than the first question.

The biggest cost factor associated with a Phase II ESA relates to the experience of the consultant chosen and their attention to the needs for the Phase II. One of the first needs is to consult with the dry cleaner on what the goals are, what the needs could be, and the costs associated with the range of possibilities for an initial Phase II ESA. The dry cleaner needs to understand what will be completed and for what cost, what the potential downsides are, and what makes the most sense for their situation. In order to do that well, your consultant needs to have experience with your business, business and technical savvy to understand the situation, and finally, the sense to know if there are other sources of funding that can eliminate or, at least, ease the cost burden.

Phase I ESA costs generally range from $1,000 to $2,500 while Phase II ESA costs vary as summarized above. Typically, a Phase II ESA can cost anywhere from $5,000 to well over $100,000. Phase II ESA initial sampling activities (to determine if there is a problem) usually cost around $5,000.

The success of the experience is tied to communication of needs and matching effort to the needs. The most important variable under the control of the owner is to pick a qualified, responsive consultant.

No matter your situation, we’re ready to find the best solution for you. Request a quote today.

As seen in Cleaner and Launderer

Stephen Henshaw, Founder at EnviroForensics & PolicyFind has over 30+ years of experience and holds professional registrations in numerous states. Henshaw serves as a client manager and technical manager on complex projects involving contaminated and derelict properties, creative litigation, deceased landowners, tax liens, non-performing banknotes, resurrecting defunct companies and cost recovery. Henshaw’s expertise includes a comprehensive understanding of past and current industry and waste handling practices and the fate and transport of chlorinated solvents in soil and groundwater. He has served as a testifying expert for plaintiffs and defendants on high profile cases involving causation and timing of releases, contaminant dispersion, allocation, damages, past costs, and closure estimates. He has a strong knowledge of state and federal regulations, insurance law, RCRA, and CERCLA. He has managed several hundred projects including landfills, solvent and petroleum refineries, foundries, metal plating shops, food processors, dry cleaners, wood treating facilities, chemical distribution facilities, aerospace manufacturing facilities, and transporters and provides strategy instrumental in funding projects and moving them to closure.

Stephen Henshaw, Founder at EnviroForensics & PolicyFind has over 30+ years of experience and holds professional registrations in numerous states. Henshaw serves as a client manager and technical manager on complex projects involving contaminated and derelict properties, creative litigation, deceased landowners, tax liens, non-performing banknotes, resurrecting defunct companies and cost recovery. Henshaw’s expertise includes a comprehensive understanding of past and current industry and waste handling practices and the fate and transport of chlorinated solvents in soil and groundwater. He has served as a testifying expert for plaintiffs and defendants on high profile cases involving causation and timing of releases, contaminant dispersion, allocation, damages, past costs, and closure estimates. He has a strong knowledge of state and federal regulations, insurance law, RCRA, and CERCLA. He has managed several hundred projects including landfills, solvent and petroleum refineries, foundries, metal plating shops, food processors, dry cleaners, wood treating facilities, chemical distribution facilities, aerospace manufacturing facilities, and transporters and provides strategy instrumental in funding projects and moving them to closure.

David O’Neill, JD, Director of Investigations at PolicyFind has 30+ years of experience in claims recovery on behalf of corporate policyholders involving environmental property damage and toxic tort and asbestos exposure claims. O’Neill has extensive experience in locating and retrieving insurance coverage evidence on behalf of potentially responsible parties responding to environmental investigation and remediation demands. His former investigative work includes unique matters involving Holocaust victims rights, mergers & acquisitions of a national landfill operator, and on matters involving national archives.

David O’Neill, JD, Director of Investigations at PolicyFind has 30+ years of experience in claims recovery on behalf of corporate policyholders involving environmental property damage and toxic tort and asbestos exposure claims. O’Neill has extensive experience in locating and retrieving insurance coverage evidence on behalf of potentially responsible parties responding to environmental investigation and remediation demands. His former investigative work includes unique matters involving Holocaust victims rights, mergers & acquisitions of a national landfill operator, and on matters involving national archives.

Steve Henshaw, P.G.

Steve Henshaw, P.G.

Teamwork by Klinke Cleaners, Wisconsin DNR and Wisconsin environmental consultants Enviroforensics keys successful dry cleaner cleanup

Teamwork by Klinke Cleaners, Wisconsin DNR and Wisconsin environmental consultants Enviroforensics keys successful dry cleaner cleanup

The headquarters building of Klinke Cleaners is located at the site of the Klinke family’s first business — Klinke Hatcheries — that Maurice and Trudy Klinke opened in the 1930s. The Klinkes pioneered coin-op laundries and self-serve drycleaners in the 1950s and 60’s, and opened their first full-service drycleaners in Madison in 1969. Now, the third generation of the Klinke family operates 21 drycleaning locations in greater Madison and Milwaukee.

The headquarters building of Klinke Cleaners is located at the site of the Klinke family’s first business — Klinke Hatcheries — that Maurice and Trudy Klinke opened in the 1930s. The Klinkes pioneered coin-op laundries and self-serve drycleaners in the 1950s and 60’s, and opened their first full-service drycleaners in Madison in 1969. Now, the third generation of the Klinke family operates 21 drycleaning locations in greater Madison and Milwaukee.

Staff Geologist

Staff Geologist