We know that chlorinated solvents tend to volatize on their own, so what happens if we use the chemical’s physical properties to cause them to volatilize even more? That’s the concept behind Thermal Conductive Heating (TCH) or Electric Resistance Heating (ERH). The idea is to heat the subsurface to such a temperature that any present contaminant becomes volatized and can be removed from the soil and groundwater. Using super-heated metal rods (TCH) or an electric current (ERH) along with some familiar applications from remedial techniques we’ve touched on in the past, a “thermal” approach can make for an effective remediation strategy for sites where other techniques are less feasible.

Excavation might not be an option if above ground structures are in the way or if contamination is too deep. Soil Vapor Extraction Systems (SVE) can prove to be an effective solution, but can prove to be equally ineffective if the contaminant plume is too deep or the concentration of the contaminant is too great. In other cases, the contamination could be resting in a patch of more dense clay soil, making it more difficult to extract contaminants. Contamination in saturated clay soil can be slowly released into groundwater over time in a process known as “back diffusion,” which makes it more difficult to achieve cleanup goals. In all these scenarios, TCH or ERH can be a viable option.

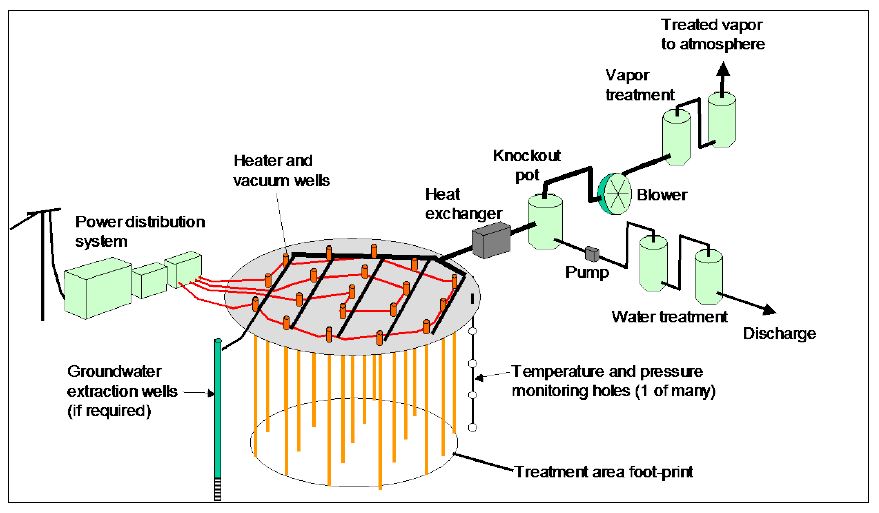

A thermal remediation system has a set of components that, working together, can effectively remove contamination from a cleanup site. The first component is the heat itself. In a TCH application, several heating rods are placed into the impacted areas to effectively raise the temperature of the ground. Additionally, a vacuum component will be installed into these wells to extract the vapor generated by the heat. If necessary, groundwater extraction wells will be installed near the heating wells to collect impacted groundwater. Treatment systems are used to remove contaminants from the water and vapor that has been extracted.

Once the thermal remediation process is started, the components operate like workers on an assembly line. Heat is applied to the subsurface, chemicals become volatized, and contamination is collected in the vapor phase by the vacuums in the heating wells. The vapors are put through a treatment component, then released into the atmosphere. Groundwater is extracted from the subsurface as well and goes through a treatment process of its own.

“Thermal” applications are considered “in-situ”, or in-place, and are perfect for sites in which demolition or excavation are not possible, or the contamination cannot be addressed by any other means.